Introduction

Electrical system failures can disrupt business operations, leading to unexpected downtime, safety risks, and high repair costs. Regular electrical inspections are the key to preventing these disruptions, but many businesses hesitate to schedule inspections due to fears of interrupting their operations.

With online electrical testing, inspections such as thermographic and partial discharge testing can be performed without shutting down equipment. This non-invasive approach allows businesses to maintain their systems’ health while keeping them fully operational, ensuring continuity and cost-efficiency. In this blog, we’ll explore why consistent online electrical inspections are crucial for keeping your business running smoothly and avoiding costly surprises.

The Importance of Regular Electrical Inspections

Minimizing Downtime Without Interrupting Operations

Electrical system failures are one of the most common causes of unplanned downtime. Many businesses, however, avoid regular testing because they don’t want to interrupt their operations. This is where online electrical testing offers a huge advantage. Technologies like thermographic inspections and partial discharge testing allow businesses to identify potential electrical problems while equipment is still running. By catching these issues early without requiring shutdowns, companies can avoid operational disruptions and continue working uninterrupted.

Ensuring Safety While Keeping Equipment Active

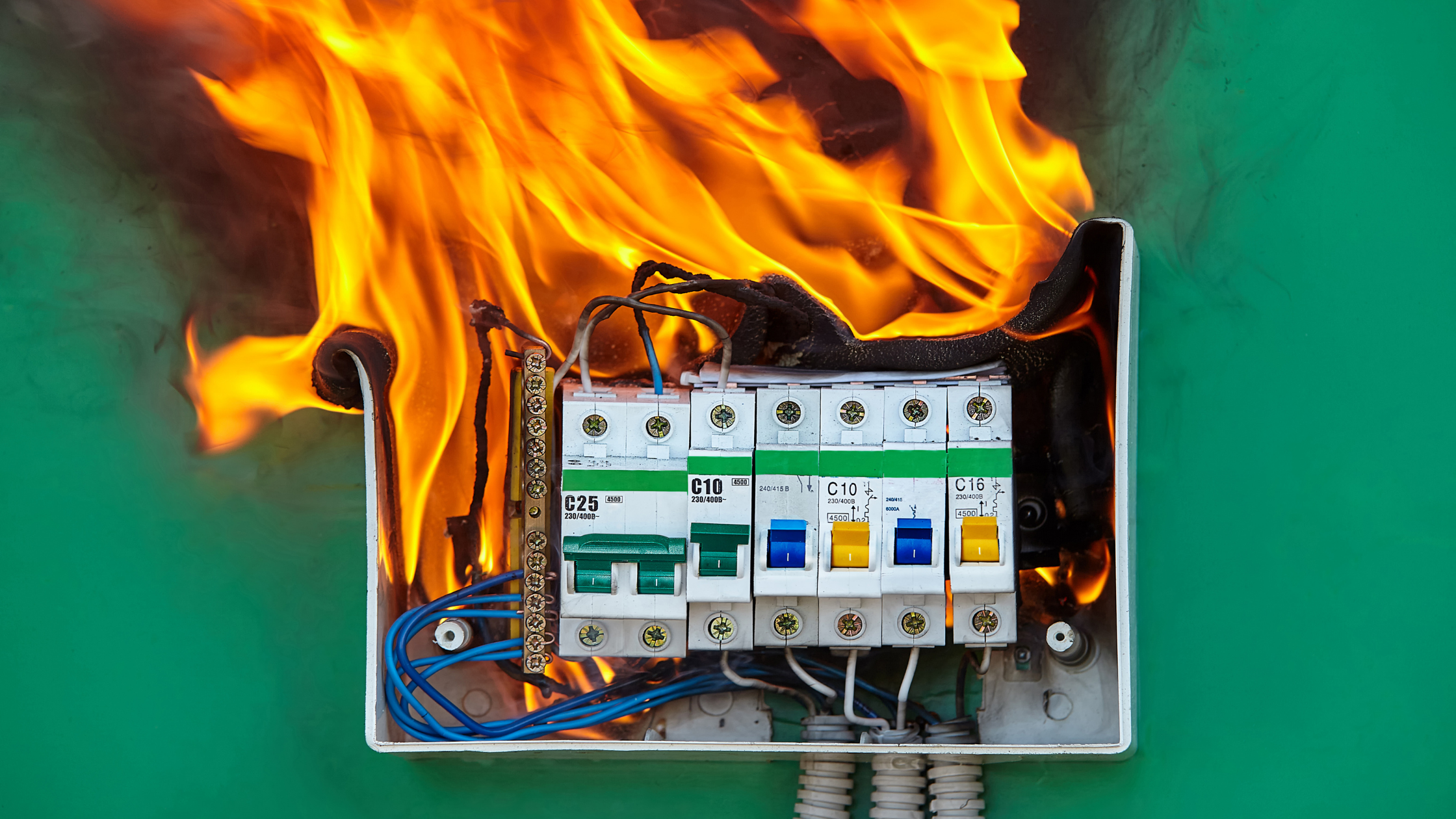

Electrical safety is essential for any business, but traditional inspections often require equipment to be taken offline, creating challenges for continuous operation. Online testing solves this issue by allowing comprehensive inspections to be performed while systems are still running. This method ensures that businesses can meet their safety obligations without pausing production or services. By identifying risks like overheating components or insulation breakdowns in real time, online testing enhances safety while keeping operations running smoothly.

Extending Equipment Lifespan with Proactive, Non-Disruptive Maintenance

Without regular inspections, small electrical issues can escalate into costly repairs and shorten the lifespan of your equipment. With online electrical testing, such as thermography and partial discharge analysis, businesses can proactively identify faults before they lead to major breakdowns. The ability to perform these tests without interrupting operations allows companies to address issues early and keep equipment in good condition for longer, avoiding the need for costly replacements and extending the life of critical electrical systems.

Key Types of Online Electrical Inspections

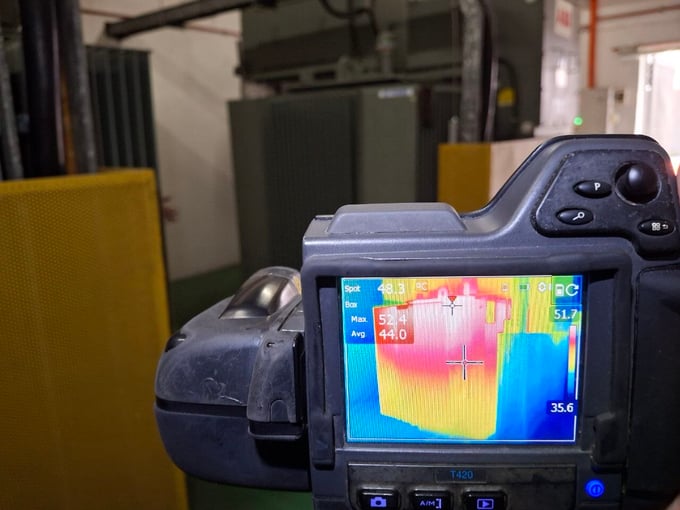

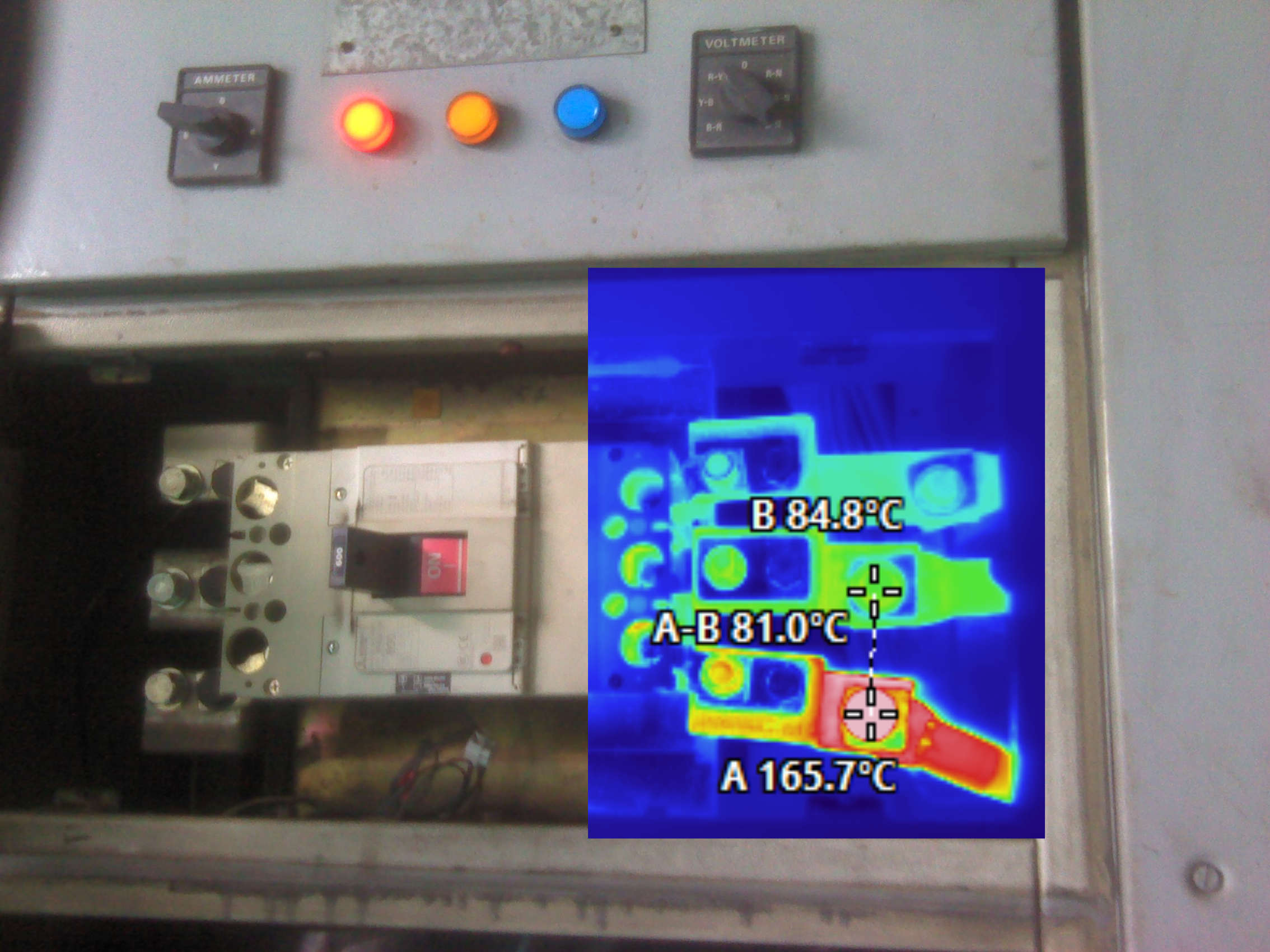

Thermographic Inspections

Thermographic inspections use infrared technology to detect heat anomalies in electrical systems—such as overheating or faulty connections—while the equipment remains operational. This form of inspection is invaluable in spotting early warning signs of potential failure, allowing companies to address issues proactively without disrupting their daily operations. By identifying areas of excessive heat, thermographic inspections help prevent equipment failures and reduce the risk of unplanned downtime.

You can learn more about this by exploring our Onsite & In-Service Thermography Assessment.

Partial Discharge Testing

Partial discharge testing is a specialized method for detecting insulation breakdowns in high-voltage systems. Insulation failures are a common cause of electrical problems, and partial discharge testing provides an early warning of these issues. Crucially, this testing can be done while systems are live, allowing businesses to identify and repair insulation problems without shutting down critical equipment. By preventing insulation breakdowns from escalating, partial discharge testing helps maintain system reliability and avoid costly repairs.

.jpg?width=680&height=510&name=Ultrasound%20(Horizontal).jpg)

For more on how this service can help your business, visit our Onsite & In-Service TEV and Ultrasound Assessment.

Long-Term Financial Benefits of Regular Inspections

Cost Savings

By implementing online electrical testing, businesses can realize significant cost savings. Early detection of potential failures prevents costly system breakdowns, which can lead to major repairs or even equipment replacements. Without the need to shut down operations for inspections, companies can keep their revenue streams flowing while maintaining the integrity of their electrical systems.

Routine inspections also reduce the likelihood of unexpected failures, which can result in lost productivity, missed deadlines, and financial penalties. Proactively addressing issues through thermographic inspections and partial discharge testing helps companies avoid these high costs, ensuring smoother operations and a healthier bottom line.

Return on Investment (ROI)

While some may view regular inspections as an additional cost, the return on investment (ROI) is substantial when looking at the bigger picture. Preventing a single major failure or avoiding downtime can far outweigh the costs of regular online testing. The ability to keep equipment in service while testing ensures that companies do not have to sacrifice productivity for safety or maintenance, maximizing both uptime and profitability.

Compliance and Safety Regulations

Meeting Local and International Standards

Compliance with safety regulations is a top priority for any business that relies on electrical systems. Many industries are required to follow strict standards to ensure the safety of both workers and equipment. Regular online electrical inspections help businesses stay compliant with local and international safety regulations, avoiding fines and legal consequences.

Whether it's fire safety standards, electrical safety codes, or industry-specific guidelines, online testing methods like thermography and partial discharge testing can help companies meet their compliance requirements. By ensuring that electrical systems are in peak condition and running safely, businesses can avoid regulatory issues that might otherwise result in operational shutdowns or financial penalties.

Avoiding Legal and Financial Penalties

Failing to adhere to safety and compliance standards can result in hefty fines or worse—legal action. In industries like manufacturing or commercial real estate, where electrical systems are critical to day-to-day operations, neglecting regular inspections can lead to serious safety hazards, including fires or electrical shocks. By performing online electrical testing, businesses can address these risks before they become compliance issues, protecting both employees and assets while avoiding costly legal and financial penalties.

Actionable Steps to Implement Regular Electrical Inspections

Set Up a Maintenance Schedule

One of the key steps in maintaining the health of your electrical systems is setting up a regular maintenance schedule. For online electrical testing, businesses should aim for quarterly or biannual inspections, depending on the complexity of their systems. A well-planned inspection schedule ensures that no potential issue goes unchecked, allowing businesses to catch early signs of trouble and address them before they escalate.

Work with Certified Experts

While online electrical testing provides significant advantages, it’s essential to work with certified professionals who specialize in thermographic and partial discharge testing. These experts have the training and experience to perform thorough inspections and provide actionable recommendations based on the results. Partnering with a trusted service provider ensures that businesses get the most out of their online testing efforts, leading to more reliable operations and fewer unexpected breakdowns.

.png?width=2547&height=1701&name=Onsite%20Condition%20Assessment%20(Dimmed).png)

To discuss how our team can help, contact us today.

Invest in Predictive Maintenance Tools

To fully leverage the benefits of online electrical testing, businesses should consider integrating predictive maintenance strategies. Thermographic and partial discharge testing are core elements of predictive maintenance, enabling businesses to identify trends in system performance and address issues proactively. Investing in these tools and regularly scheduling inspections helps businesses avoid the costs and disruptions associated with reactive maintenance, keeping operations running smoothly in the long term.

Conclusion

In today’s fast-paced business world, ensuring the reliability of your electrical systems is critical to avoiding costly downtime, ensuring safety, and maintaining operational efficiency. Regular online electrical inspections, such as thermographic and partial discharge testing, allow companies to stay ahead of potential failures without disrupting their operations. These inspections not only help businesses maintain compliance with safety standards but also extend the life of their equipment and provide significant cost savings.

By incorporating consistent electrical inspections into your maintenance routine, you can protect your business from unexpected disruptions, reduce repair costs, and ensure that your equipment operates at peak performance. Schedule your next online electrical inspection today and keep your business running smoothly.